Upper Peninsula Well Represented Among NextCycle Michigan Teams

Recyclers and composters in Michigan’s Upper Peninsula (U.P.) face all the challenges of lower Michigan’s rural areas:

Lack of convenient access to recycling for households and businesses

Local economic challenges make funding difficult,

Often being overlooked for business oppo rtunities and state and federal resources, and

Logistics challenges—having a lot of area to cover as well as longer distances to processing facilities and end markets.

NextCycle Michigan Accelerator Tracks

NextCycle Michigan is designed to connect entrepreneurs, companies, organizations, and communities with technical support, financial resources, and capacity building for recycling, recovery, and reuse initiatives. The program is divided into tracks based on project focus. The three tracks that hosted U.P. teams include:

Intergovernmental Initiatives and Public-Private Partnerships (I2P3): Focuses on projects led by public-sector entities seeking to improve recycling and composting in their communities.

Food, Liquids, and Organic Waste Systems (FLOWS): Businesses, public-sector entities, and nonprofits pursuing recovery of organic materials, composting, anaerobic digestion projects, and new uses and end markets.

Recycling Innovation and Technology (RIT): Fosters the development and commercialization of technologies, new uses for recovered materials, and other innovations across the reuse, recycling, and organics value chains.

And in much of the U.P., “rural” is an understatement. In fact, according to The Munising Beacon, the peninsula has approximately 30% of Michigan’s landmass but just 3% of its population. To top it off, it’s not unusual for many areas of the U.P. to get over 150 inches of snow annually (National Weather Service).

The result has been a recycling capture rate of less than 2%, compared with approximately 20% statewide (CUPPAD).

However, according to the Central Upper Peninsula Planning and Development Regional Commission (CUPPAD),

Surveys of U.P. residents have shown that people want to recycle, and that those who do are willing to drive to locations to participate. Businesses in the region have incorporated recycling into their sustainability or material-sourcing plans, creating more demand for products, new entrepreneurial activities, and greater awareness of the economic and environmental benefits.

Further, CUPPAD reports that “Few cities and townships currently have agreements or infrastructure in place to collect recyclable materials, however, citizens and businesses are engaged in recycling efforts, and there is a growing market for recycled materials used in manufacturing.”

U.P. residents’ enthusiasm for sustainable materials management is reflected in their remarkable representation among teams taking part in the Nextcycle Michigan Accelerator program, a Michigan Department of Environment, Great Lakes, and Energy (EGLE) initiative. Seven percent of NextCycle Michigan teams to date have hailed from the U.P. — disproportionately high for 3% of the state’s population!

Of the eight U.P.-based teams to date, four set out to develop local recycling programs, three focused on composting projects, and one is commercializing an innovative technology. Let’s learn more about a few of these projects.

Collabortive RECYCLE SYSTEMs

Two U.P. teams accelerated efforts to develop county recycling programs, summarized below. To understand them, it is important to be aware of the efforts of the Marquette County Solid Waste Management Authority. They are known by their call to action, Recycle 906. The number 906 here refers to their area code which encompasses the entire U.P.

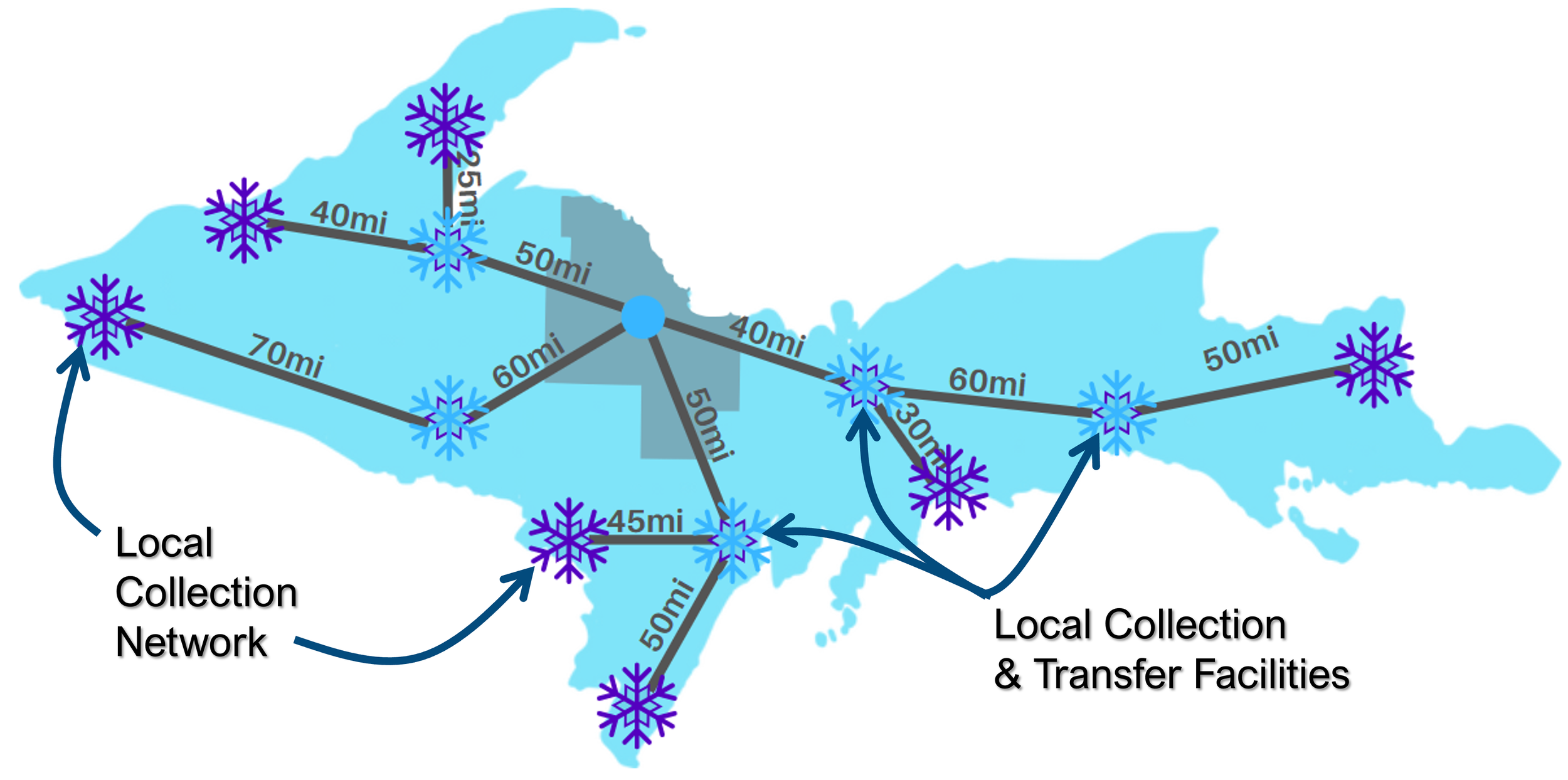

Recycle 906 developed a modern materials recovery facility and has made it known that it is willing and able to contract with all 15 counties of the U.P. to sort and market their recyclable cardboard, paper, and containers. By creating this reliable hub-and-spoke processing opportunity, Recycle 906 has supported a flurry of recycling improvements in the region. Both featured NextCycle Michigan U.P. community recycling projects plan to use Recycle 906 as their processing partner.

dICKINSON CONSERVATION dISTRICT

The Dickinson Conservation District used the NextCycle Michigan I2P3 accelerator to get down to the practical details of their plan to provide curbside recycling for the towns of Iron Mountain, Kingsford, and Norway and recycle drop-off sites to serve the seven townships in the district. With the help of NextCycle Michigan coaches and mentors, the team:

Collection and transfer infrastructure that can be scaled and deployed in a large hub-and-spoke system as participation grows. Source: Dickinson Conservation District.

analyzed three proposed recycling drop sites,

looked at partnership structures for their work with Recycle 906 and Trico Opportunities,

used NextCycle Michigan data resources to model capital and operational costs, and

created a presentation to educate local government officials and residents about operational funding options.

Once the district has operational funding in place, it plans to seek grants from EGLE and other funders to help with the system’s capital needs.

tHE u.p. rECYCLING cOLLABORATIVE

The other U.P. project to establish local recycling programs began as three projects, for Alger and Schoolcraft counties and the HSC (Hiawatha Sportsmens Club) Foundation. When their proximity and shared goals were recognized, they formed one NextCycle Michigan team — the U.P. Recycling Collaborative. Working together and in cooperation with the Central Upper Peninsula Planning and Development Regional Commission (CUPPAD), they developed a compelling strategic plan for sustainable materials recovery across the entire U.P.

With Michigan counties heading into the state’s updated Materials Management Plan process (formerly Solid Waste Management Planning), Ryan Carrig of CUPPAD said,

“..we are fortunate to have been involved in NextCycle to get the ball rolling early on coordinated materials management. Looking back, I have to say that, roughly 18 months later, we’re on track with what we pitched and are building towards the larger goal, though we know there are going to be issues along the way. We’re also fortunate to have met other NextCycle partners who are going to be involved in our materials management planning as well.

Recycling Innovation and Technology

Revex

The Revex (formerly Nion Metals) NextCycle Michigan team was a collaboration between the emerging company, Michigan Technological University, Eagle Mine, and the MTEC SmartZone — a business and technology incubator in Houghton-Hancock, Michigan. The team participated in the NextCycle Michigan RIT Accelerator Track to advance the scale-up and commercialization of a process for recycling used lithium battery materials and extracting additional critical minerals from mine tailings (waste).

Source: Revex

Through the NextCycle Michigan Accelerator, Revex connected with key industry partners and increased their understanding of battery recycling and manufacturing supply chains. They also furthered the development of their strategic plan, changing the team’s structure and setting milestones for the next three years. John Rockwell, Revex’s CEO, founder, and managing director said of the team’s experience in the program:

Going through the NextCycle Michigan program at the stage of our company — where we’ve just formed it and are trying to develop the first product — introduced us to some investors who understand the space and helped with access to numerous sources of non-diluted funding. Getting ready for the showcase was very interesting. You’re developing your business and you’ve got an idea of what you want to do, but now you’ve got to present it to an audience and get it concise.

Food, Liquids & Organic Waste Systems

WUPPDR for Houghton County Community Composting Pilot Project

The Western Upper Peninsula Planning and Development Region (WUPPDR) NextCycle Michigan project is piloting a community-supported, locally operated compost facility in Houghton County on a site provided by Osceola Township. The team firmed up details of their vision of processing food scraps collected from residents, restaurants, schools and other small institutions in combination with wood shavings and chips, manure, and leaves from municipalities and other businesses.

Houghton Farmers Market. Source: WUPPDR

The WUPPDR team emphasized the strong local demand for compost due to poor soil and a lack of local compost sources. Area farms and landscapers have been importing compost and soil products from out of state.

NextCycle Michigan team member Evan Lanese, GIS and planning technician at WUPPDR, said, “The accelerator really connected us with the expertise that we needed to move this project forward, figure out some of the practical details, and have a solid plan to present. It makes me feel really excited to be able to bring this to my community now and feel confident that we've had professionals behind it.”

At press time, Lanese reported that the project is moving forward in working with more partners including the Michigan Technological University (MTU) dining halls and MTU’s Forestry Soils Lab which will test samples of their compost products. Isle Royale National Park has expressed interest in working with the composters in the future, too. As part of NextCycle Michigan, the Centrepolis Accelerator extended a U.S. Economic Development Administration (EDA) Build to Scale grant to the project. The grant is providing technical support to develop engineering plans for the site. The team is also applying for a grant to cover the start-up costs of the pilot including construction, equipment, and expenses to operate the composting site for one year.

The Bioenergy Project

The BioEnergy Project is developing an easily shipped, flexible, and affordable organic-waste management system that can be adapted to yield clean water, compost, liquid fertilizer, and/or biogas fuel. The team’s first prototype won the prestigious Lemolson-MIT Student Prize in 2019. The team envisions its systems serving wastewater treatment needs in areas facing natural disasters, as well as households, farms, businesses, and institutions.

With the support of the NextCycle Michigan FLOWS Accelerator Track, the team:

identified potential funding sources for a trial digester at the Copper Island Academy (a K-8 charter school in Calumet, Michigan)

outlined a cost/revenue framework for operating the school-level unit,

developed a business model for selling the units including a go-to-market strategy and a six-year financial forecast, and

explored intellectual property considerations.

Roughly a year after completing the NextCycle Michigan program, The BioEnergy Project is in talks with a missionary group in Liberia to use the system to bring quick, affordable water treatment to a community that needs it while serving as a technical validation project for the device. They are seeking financial sponsors for this endeavor.

Partridge Creek Farm Organic Waste and Compost Project

The Partridge Creek Compost (PCC) team is working to solve three local challenges:

The U.P. imports 90% of its food.

60% of waste in Marquette County is compostable.

The area has thin topsoil.

The team proposes a three-pronged approach through targeted partnerships to grow more food locally, divert compostables from landfilling, and produce compost for use in building local farmland.

Building on existing partnerships with the Lions Club International, Northern Michigan University, the Ishpeming Public Schools, and the City of Ishpeming, PCC used technical assistance provided through NextCycle Michigan to address operational, regulatory, and permitting issues in expanding its composting site.