Recycling Robots Come to Michigan

Artificial intelligence, machine learning, neural network training – these are concepts that you would expect to explore in a summer sci-fi movie. But while Skynet has failed to gain a foothold beyond a parade of subpar sequels, AMP Robotics is blazing a trail in the living and breathing operations of material recovery facilities (MRFs) throughout the U.S., and now in Michigan.

The Challenge

It is well understood that the economics of comingled recycling is challenging. Typical MRF operations require a significant amount of manual labor to separate materials into marketable commodities and remove contaminants. Using this typical configuration, the cost to sort one ton of mixed recyclables is currently greater than the revenue that the resulting commodities can generate.

The material stream is evolving, contamination is increasing, end markets are looking for cleaner material and tightening labor markets make it difficult to adequately staff sort lines.

These issues are further exacerbated by COVID-19. MRFs and their employees have been deemed essential, so the sorting has not stopped throughout the pandemic. However, finding workers to handle other peoples’ waste has become even more difficult and many facilities have faced outbreaks, diminishing staff availability due to illness.

At the Emmet County MRF in Harbor Springs, Michigan, changes in the recycling stream, growing contamination, and a tight labor pool have been ever-present obstacles to the operation.

The SOlution

This is beginning to change with the use of robotics to automate sort lines and improve quality and efficiency of MRF operations. AMP Robotics is a leading waste tech firm focused on automation and has been on a rapid growth trajectory with over 100 units added to the field since 2017.

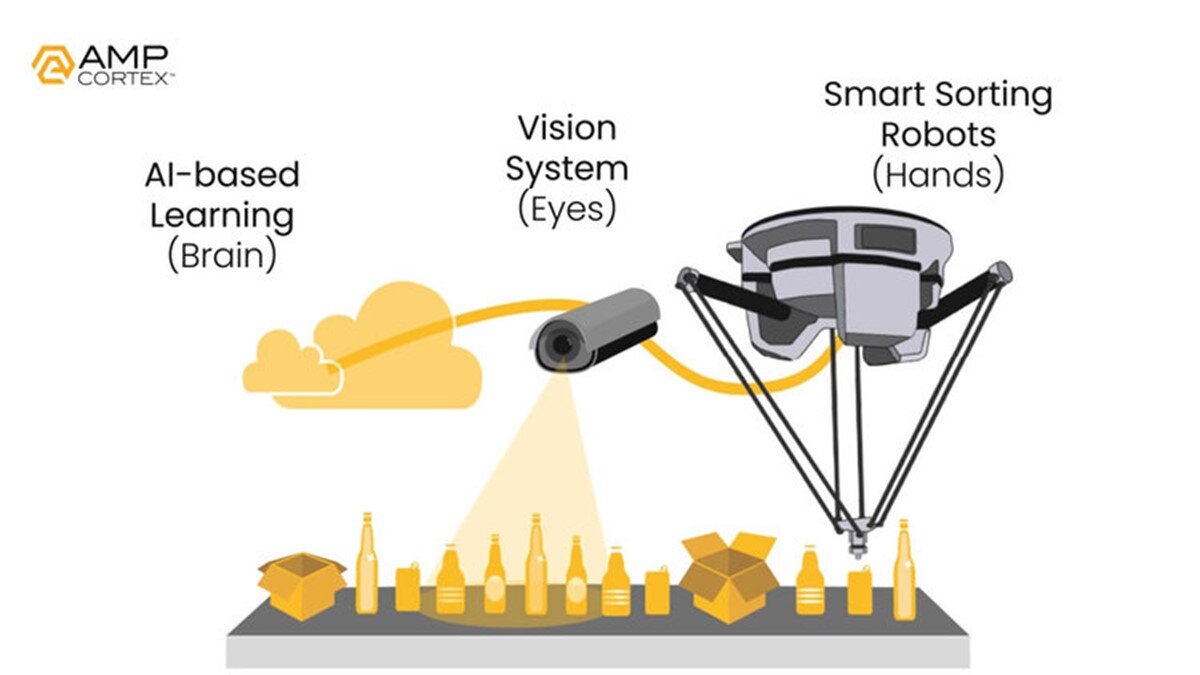

AMP uses artificial intelligence (AI) technology along with a proprietary vision system to identify and sort different types of recyclable items. Through neural network training – teaching the AI inputs and outputs - the system can properly identify things that can be difficult for a human, such as recognizing the type of plastic resin as a container moves past on the conveyor. It can also learn to identify the shape of materials, even when crushed or flattened, to further bolster material categorization.

This level of sorting allows recovery facilities to produce recycled commodities that are cleaner, more valuable, and facilitate recycling into new products. It also increases efficiency and capacity by extending operating hours with minimal additional workforce. Emmet County Recycling took advantage of the technological advances and upgraded its decade-old container sorting line to include robotic sorters.

The Team

Although the improvements are expected to pay for themselves over time, a significant part of this project was raising capital to cover up-front costs for the $2.4 million worth of upgrades. To finance this, the county received an $800,000 infrastructure grant from the Michigan Department of Environment, Great Lakes, and Energy (EGLE) in 2019 and an interest free loan of $100,000 from the Closed Loop Fund. Other support was provided by the Carton Council and the Petoskey-Harbor Springs Area Community Foundation.

Machinex was the chosen contractor for the installation and much of the equipment, while AMP provided the robots. Resource Recycling Systems (RRS), led by project engineer Kerry Sandford, led the execution of the project.

The Results

The dual stream facility began operations with the upgraded sort line on October 12, 2020. The new sorting line consists of a glass breaker on the front end (where glass is sorted out), followed by a manual presort (where bulky items and trash are manually removed), which leads to an overhead magnet (where steel cans are sorted out), and then to the robotic sorting line. The robotic sorting line contains three robotic sorting units which use air suction to grab and sort aluminum foil, cans and trays, paper cartons and cups, and three categories of plastic containers from the stream. After the first pass of robotic sorting the left-over material is loaded into a hopper where it is stored until it is re-run through the robotic sort line to capture any recyclable material missed on the first pass. The re-running of material can take place with minimal human supervision and allows for sorting staff to be assigned other tasks at that time, such as fiber sorting. It also ensures that the maximum amount of recyclable material is recovered.

The program is open to expanding its service range, and the new equipment/upgrade makes that possible. Emmet County Recycling already takes more materials than any other program in the state. As end markets develop and make more materials viable for recycling, the new configuration allows for increased flexibility to add additional material and package types.

Video

Courtesy of Amp Robotics