Small Investments Overcome Big Barriers: Kalamazoo Craft Brewers’ Recycling COoperative

The Challenge

Everyone knows of Detroit as the Motor City. As far as nicknames go, MoTown is as ubiquitous as the Big Apple or the Windy City. On the other side of the state, Beer City has taken hold as the calling card for Grand Rapids. But just as the auto industry is a regional goliath, the Michigan Craft Beer revolution is thriving in Western Michigan, including Kalamazoo, which is home to several breweries.

The ingredients for brewing beer are simple - water, hops, yeast, and barley. Brewers have a multitude of well-developed methods for using these inputs efficiently and sustainably. However, the packaging in which these materials are delivered to the brewer can be problematic, and in some instances, lack systems for reuse or recycling.

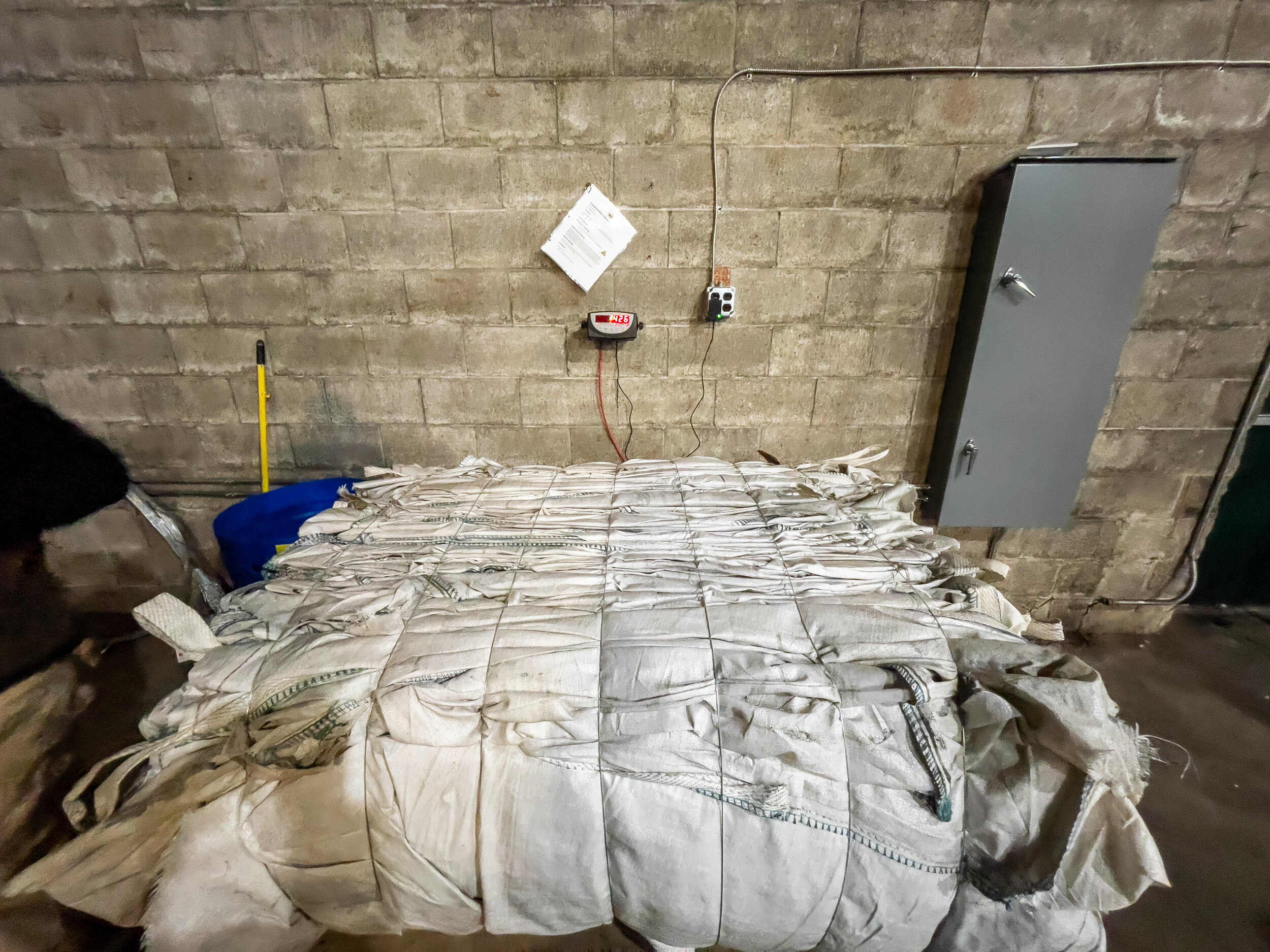

In particular, the bags used to package barley and other brewing grains are made of woven polypropylene, which is a recyclable material, yet prior to this grant project, not a single brewer in the Kalamazoo area had access to a viable recycling outlet for their grain bags.

The reason for this is relatively simple. Woven polypropylene is a low-value commodity in the recycling economy and its worth is dependent on truckload quantities of baled material. Individual breweries do not generate enough material to fill truckloads, nor do any of them have access to the equipment required to bale the material. This is a basic problem of scale and processing equipment.

The Team

A collaboration between The Kalamazoo Nature Center and Bell’s Brewery joined forces, to identify possible solutions. Other local breweries were engaged informally.

The SOlution

The team applied for and was awarded a modest Recycling Infrastructure Grant from the Michigan Department of Environment, Great Lakes, and Energy (EGLE) to purchase two balers to resolve these barriers.

The Kalamazoo Nature Center, which aspires to promote and enable sustainable business practices, facilitates the grant, while Bell’s Brewery houses and operates the baling equipment. Local brewing and manufacturing partners participate by collecting and dropping off their generated materials to Bell’s.

An added benefit of this project is the utilization of the second baler for consolidating cardboard (OCC) from participating partners. This allows the program to generate revenue while also reducing the costs participating breweries incur to operate their own small-scale recycling programs. Finished bales of grain bags and cardboard will be sold to Padnos Recycling in Grand Rapids. The commodity revenue will sustain the program’s operations.

The Results

The program is expected to divert over 26,000 lbs of polypropylene per year from Michigan landfills and provides a replicable model for using partnerships and modest funding support to overcome frustrating barriers to recycling.